Rock wool board is made of select fine basalt as the major materials which is pulled into 4-7µ non-continuous fibers...

Product parameters

| Density | Thickness | |||||

| kg/m3 | mm | |||||

| 60 | 50 | 70 | 80 | 100 | 150 | / |

| 75 | 50 | 70 | 80 | 100 | 150 | / |

| 80 | 50 | 70 | 80 | 100 | 150 | / |

| 100 | 50 | 70 | 80 | 100 | 150 | / |

| 120 | 30 | 40 | 50 | 80 | 100 | / |

| 130 | 30 | 40 | 50 | 70 | 80 | 100 |

| 150 | 30 | 40 | 50 | 70 | 80 | 100 |

| 180 | 30 | 40 | 50 | 70 | 80 | 100 |

| 200 | 30 | 40 | 50 | 70 | 80 | 100 |

Product Features

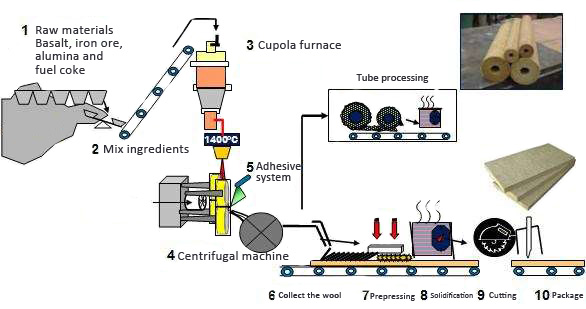

Rock wool board is made of select fine basalt as the major materials which is pulled into 4-7µ non-continuous fibers after melted by adopting advanced international four-roller centrifugal cotton-making procedures and adding a certain of adhesives, dust laying oil and water repellent into rock wool fibers. It can be made into products series with different density according to various uses through the technology of sedimentation, solidify, cutting and etc.

Our advantages:

1. Superior Fire Resistance

2. Good Water reprellence

3. Environment Friendly

4. Stable Insulation Performance

5. Excellent Acoustics

6. No Corrosion On Insulation Body

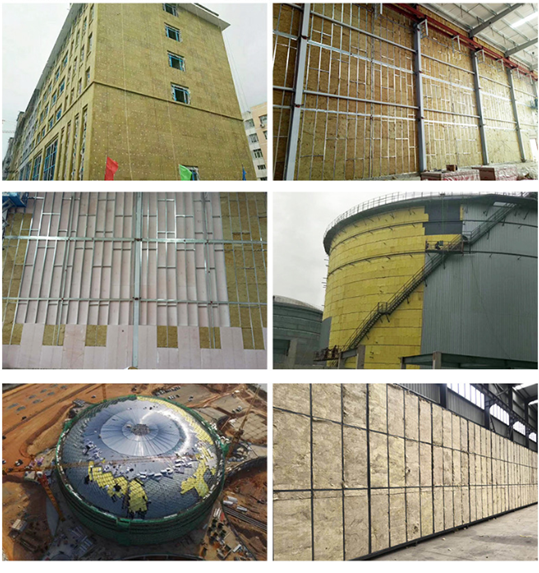

Application of rock wool:

Rock wool was used for building materials, and steel structure insulation

soundproof and fireproof used for wall and roof of house

Heat preservation for steel structure building

Heat Insulation for wall and roof of house to save energy

For indoor partition wall, Train compartment.

Rock wool board for ship thermal insulation and fire prevention partition keel interlayer sound insulation; Rock wool for building has excellent fire prevention, heat preservation and sound absorption performance. It is mainly used for building wall, roof insulation; Fire prevention and noise reduction of building partitions, firewalls, fire doors and elevator shafts.

The rock wool production process

TECHNICAL INDICATORS

| Properties | Value |

| Density | 60-150 Kg/m3 |

| Shot content (particle diameter ≥0.25mm), % | ≤12.0 |

| Average fiber diameter, μm | ≤7.0 |

| Density tolerance, % | +15, -15 |

| Thermal conductivity coefficient (average temperature: 70±2℃), W/(m. K) | ≤0.043 |

| Thermal load contraction temperature (products with density above 60kg/m3), | ≤ 600 |

| Acidity coefficient mk | ≥ 1.6 |

| Moisture content, % | ≤0.5 |

| Combustion property | Non-combustible(A class) |

| Organic material content, % | ≤ 4.0 |

| Water repellence (water-proof), % | ≥ 98 |

| Water absorption (water-proof), % | ≤ 5 |

| Max Application Temperature ℃ | 650 |

FAQ

FAQ

1. Are you a manufacturer or a trading company?

We are a manufacturer which has 30 years' history.

2. Can you accept OEM or ODM?

Of course, Logo is also acceptable.

3. What is the delivery time?

About 10-20 days after the contract signing.

4. What is your payment methods?

T/T L/C Paypal West Union and others .

5. Where is your manufacturer? How to visit it?

Our factory located in Binhai New Area, Tianjin, China. Mainly producing pre-insulated pipes, mineral wool insulation products and other insulating materials. You can take a plane to Beijing or Tianjin, then take a train to our company.

6. How do we control our products' quality?

We have professional quality control workers and quality inspection machine to control the entire production quality. We can also provide an inspection which was offered by a third party.

7. Can I customize some other sizes of products?

Yes! We can according to the customer's request. If you have any other questions, please don't hesitate, contact us.

SERVICE

SERVICE

1. Timely response: to your inquiry in 24 hours, quickly respond mails and provide solutions.

2. Free sample: Sample and trial order are accepted for the quality evaluation.

3. Shorter delivery time: Book the earliest vessel or plane to guarantee the delivery time.

4. Professional Services: Provide high or cold temperature solutions and professionals installation and technology services for you.

Rock Wool Blanket Rock Wool is made from basalt, an inorganic raw material. It is produced through heating basalt at 1350˚C - 1400˚C and transforming it into fibers

Rock Wool Blanket Rock Wool is made from basalt, an inorganic raw material. It is produced through heating basalt at 1350˚C - 1400˚C and transforming it into fibers

Copyright © Tianjin Haimen Building Materials Co., Ltd. All Rights Reserved

Sitemap